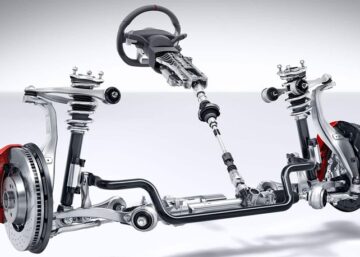

The continuous development and innovation of new products are always making the manufacturing industry to be a global dominance. In new product development, prototype plays a role of importance. It’s proof of the designers’ concept. Physical objects are constructed or prototyped according to design to check if ideal function and appearance are workable. The prototype is also a validation before designs going into production. Generally, several prototype iterations are required before new product designs put into production. Prototype development can be partitioned into 5 phases, each phase is a step forward towards concept accomplishment.

Rapid Prototyping Tech Promotes Prototype Development

Prototype design is the first product made in consideration of the original idea. In this process, tools like jigs, fixtures, and dies are not specifically manufactured for mass production. Machinists often use any tools they have to complete the work. Prototyping is indeed a time-consuming process, because each stage of it is like a first trial, and there is no pre-established technology or process. In addition, engineers must deal with errors and trials throughout the prototype process. In manufacturing, engineering companies take prototype development as a commercial contract and set up all the equipment needed to complete the project.

Ready for Appearance Model

The product development process is not an easy battle. Most startups underestimate the time or effort required for the whole process.

Easily making preliminary prototypes leads to a false sense of progress to developers. Many of them have made huge visual advancements in the early phases, creating products similar to the finished product in appearance and function, thus making them feel like they’ve made great progress while actually they still have two to three times more work to do. The remaining works including design and manufacturing, engineering and testing to the manufacturing phase.

It is often said that details determine success or failure, especially in actual product design.

Most people don’t realize that just because you have a prototype that looks and feels like a finished product does not mean that you are ready for production. Details such as material selection, components, tolerance analysis, assembly sequence, applicability, design verification, and certification all need to be formulated.

Supports of Design for Manufacture (DFM)

Design and manufacture (DFM) is the process of designing your product to make it easy to manufacture. This is a critical manufacturing design tool and process before manufacturing new products. If done well, DFM will guarantee quality and productivity.

- DFM Makes Sure Your Product Can Actually Be Manufactured

DFM begins after the design drawings are finalized and prototyped to verify the design concept. It reinvents the product in a production facility environment, not in an R&D lab or computer simulation. In the manufacturing process, it is very challenging to achieve the design characteristics of the components or the performance of the system. In the worst case, the product design may not even be manufactured, it has to be redesigned.

- DFM Makes a Huge Sense on Your Products

DFM includes all design of the BOM project and final assemblies, such as mold layout, heat transfer analysis, tooling design, and manufacturing process design. Only with properly designed tools can the correct look, feel, precision, and function of the product be achieved.

- DFM Can Greatly Affect Your Schedule

When creating a project schedule, DFM is often ignored, but it should not be ignored. Generally speaking, DFM can switch back and forth from one week to several weeks according to the quality requirements and the complexity of new products. Step by step, every detail of DFMs needs to be verified and confirmed with the product designer as much as possible to eliminate potential errors that may take a lot of time and money to recover later.

It is important to understand that any adjustments that need to be made during the design and manufacturing process will take time and affect the entire timeline. However, in the long run, the returns will be greater.

Proof of Concept Prototype

The POC (Proof of Concept) method allows sharing internal knowledge between teams, exploring emerging technologies, and providing proof of concept for customers’ products. Firstly, the developers assigned to the POC conduct research and start to develop features, the purpose is to prove that it is feasible. Once it is proven, the POC will be expanded to develop an integrated working model to provide a fragment of the final product.

After that, it will either present to customers and product teams to promote the idea of upcoming projects, or it can be used within the development team to share knowledge and stimulate innovation.

Pilot Production & Matured Production

A pilot production & matured production often results in showing customers a better product, lower development and manufacturing costs, more efficient plant operations, and earlier product introduction.

With the engineering development of products, processes, or complex equipment and its unique manufacturing in the model workshop, it is proved that the development is desirable and necessary on the basis of a simulated factory.

From concept to reality, innovation needs to be speedy.

In this era of rapid development, tens of thousands of new products are born every day, so the speed of product development is extremely important.

Technology integration makes it possible for product design, material engineering, test engineering, and advanced manufacturing processes to quickly bring products to market according to customer strategies and product concepts. Through technology integration, we quickly bring product design, material engineering, testing engineering, and advanced manufacturing processes to the market in accordance with our customers’ strategies and product concepts.

Our experienced engineers transform customer designs into product prototypes in an efficient, high-quality, and low-cost manner. Our services include product design feasibility analysis, product manufacturability analysis, and assist the innovation team in rapid product development and small batch trial production. The core of our prototype development service is speed. We provide a quick quotation and start project cooperation quickly.